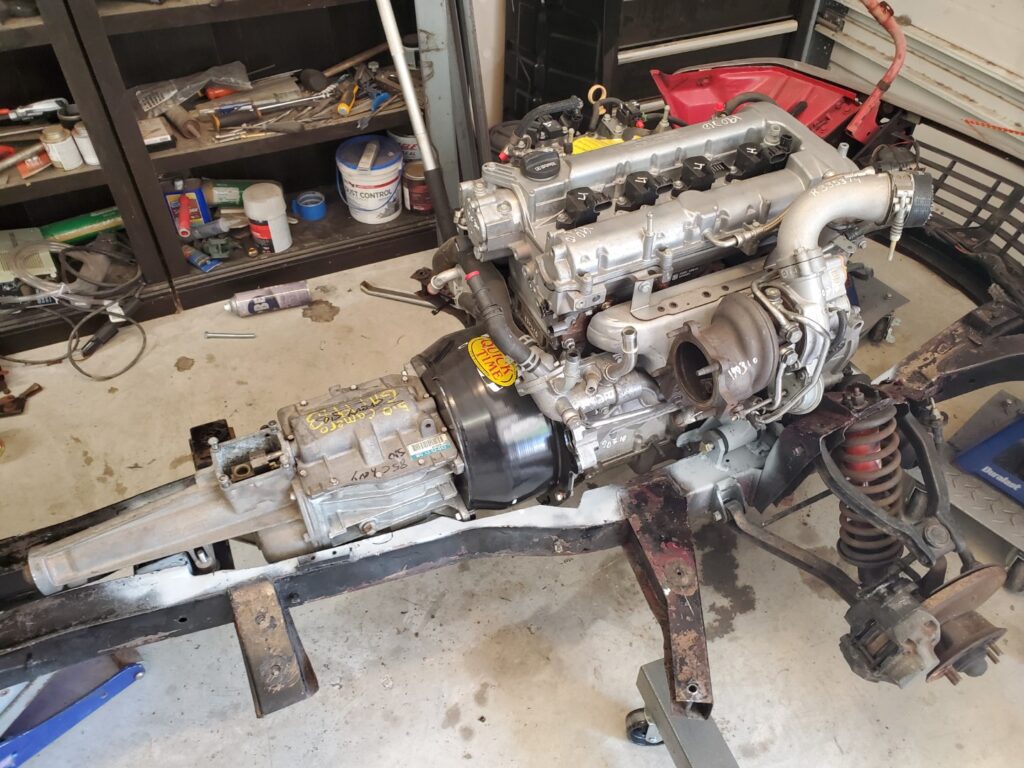

I’m happy to say I finally have the Ecotec LNF engine and Chevy T5 transmission fitted into the GT6! This was a substantial amount of work, and even now it’s not done. I documented in a previous post how I boxed the frame where I had to make cuts, but I also plan on laddering the frame where possible with 1.5″ DOM tubing to help reinforce everything.

I was able to get the engine seated low enough to clear the bonnet without modifications, which was a big deal to me as I love the stock curves of the GT6 and didn’t want to mess with it. The trade-off was putting the oil pan lower than I would like, with about 1.5″ below the frame. I am not sure if this will be an issue, but I will definitely keep an eye on it and add a skid plate if needed.

I made my own engine and transmission mounts using some beefy steel in the stock mount locations on the engine with polyurethane bushings and 9/16″ G8 bolts, so she should not be going anywhere. I ended up with about 1/2″ of clearance on each side of the engine to the shock towers. Unfortunately I did have to remove a lot of the buttressing on the shock towers, but I plan on making this up with some 3/8″ steel reinforcements as well as building a strut brace that will connect the towers in front of the engine. More on that in a later post.

Sadly, I was unable to fit the AC compressor anywhere of value. I am not giving up on that though. I refuse to not have AC. If I have to, I will run a tiny driveshaft the length of the car and put the compressor in the trunk section. We’ll see what happens, but it will have AC.

In this first set of pictures, you can see the engine and transmission sitting on the stock frame and just how much clearance will have to be done to lower it enough.

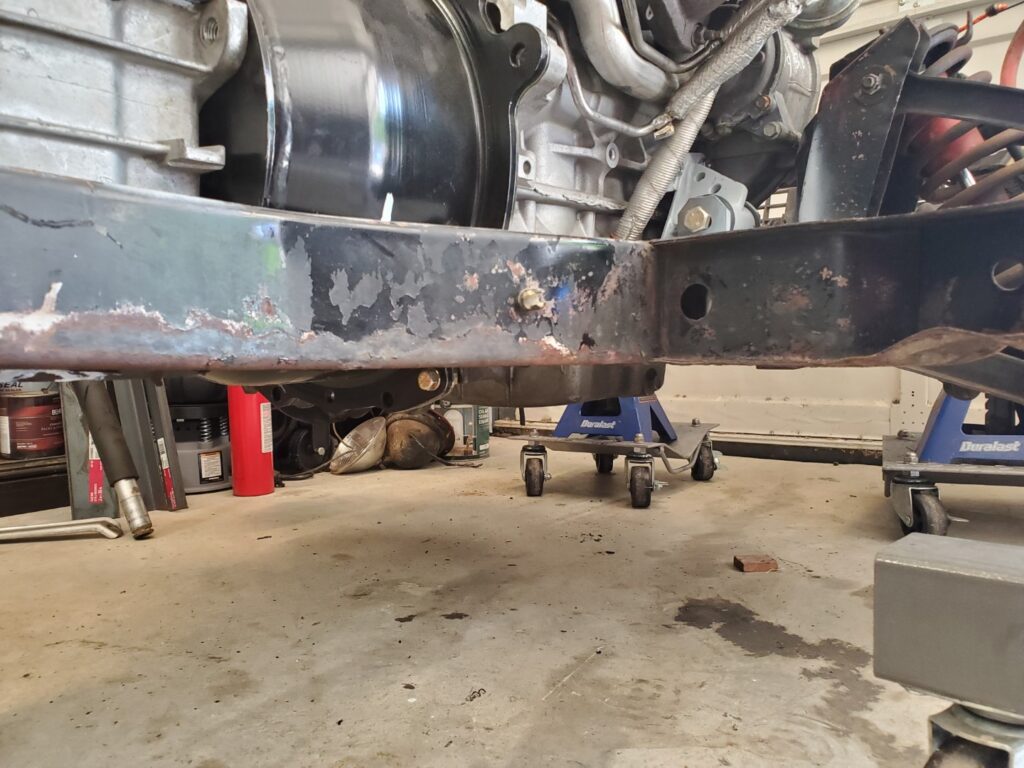

And here you can see the final result, finally sitting on her own three legs. Should be a wild ride when done!