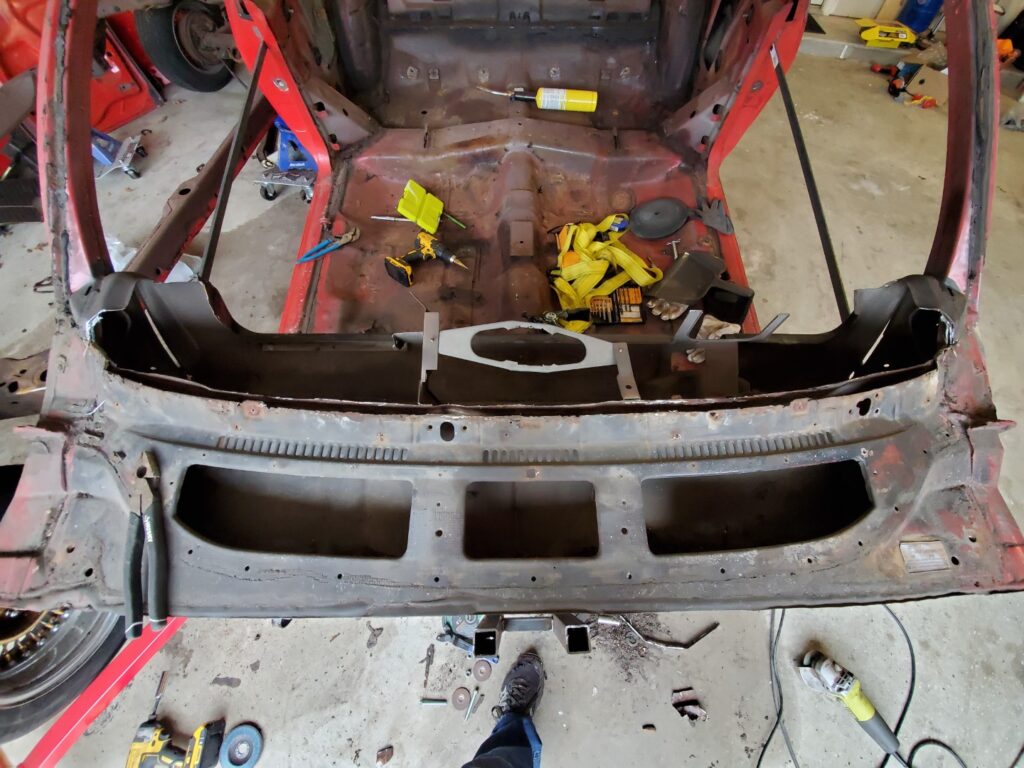

After getting the windshield off, one of the first things I noticed was how bad the lower windshield channel was. It was completely rusted through to the interior in some places, and was overall in just terrible shape. This is a super important area to have water-tight, as all the water from the windshield runs down here and would go straight into the dash and foot well. Fixing it was the first bit of sheet metal and body work I have done to the car. There was literally only 8″ of the front of the dash that was actually still intact enough to be spot welded to the lower windshield channel.

So I set about cutting the dash out, then cutting out the lower windshield channel (which was so rusted through that most of it just fell out.

After that, it was just a matter of trimming up the replacement panel and welding in. First I tacked it in a few areas to get everything lined up, then I tacked between those, and so on, until I had a basically continuous weld. This was really slow, but helped keep burning through the metal to a bare minimum. Finally, I spent an hour or two grinding/sanding down the welds, and hit it with a coat of weld through primer. I am really proud of how it came out, and know it will definitely be 100x better than the rust/metal that was there. I even think it looks pretty good, but sadly all of this will be covered by trim when the car is done!